GST Registered – 23ACDFM9864H1ZX

MS Angle

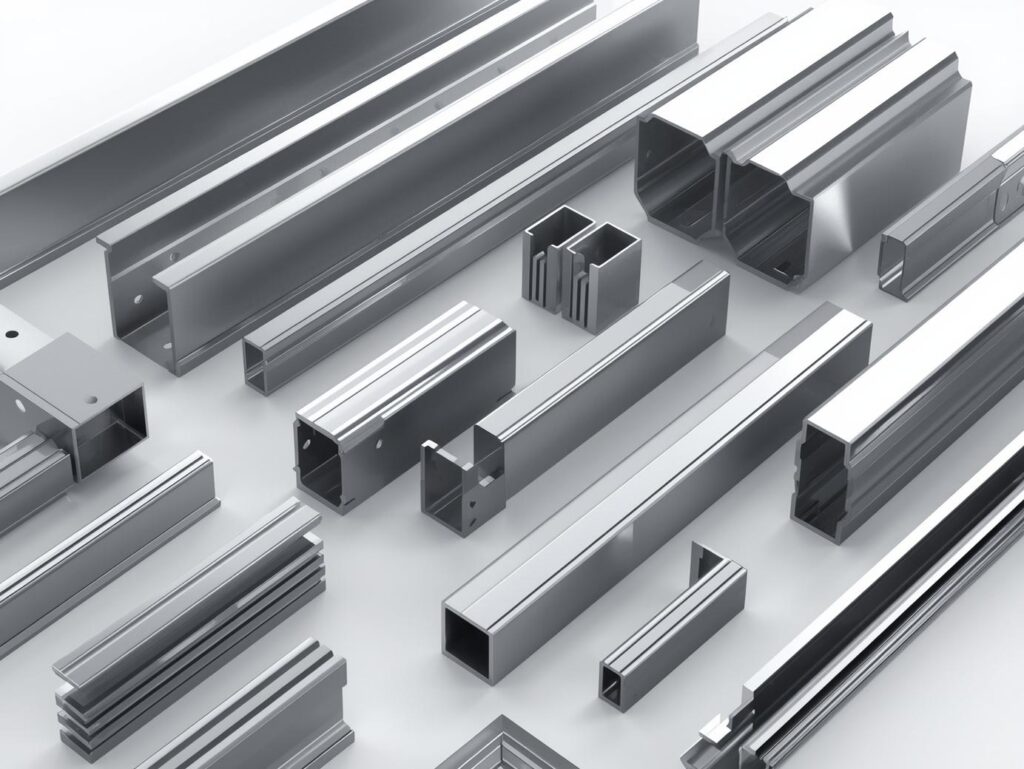

MS Angle – Mild Steel Angle of the Highest Quality.

An MS Angle is a Mild Steel Angle that has a structural steel product with an L-shaped cross section. Because of its strength, durability and cost-effectiveness, it is valuable in construction and fabrication as it is the key structural process in work. These angles are commonly used in one of two ways, structural reinforcements or structural supports and frames in buildings, bridges, towers and industrial Projects.

There are two types of MS Angles:

* Equal Angles – both sides have the same lengths and thicknesses

* Unequal Angles – one side is longer than the other and adds flexibility in design and

support.

Categories of Mild Steel Angles

In addition to equal and unequal sections, MS angles come in special shapes, such as:

- T angles - useful in engineering and fabrication.

- V angles - recognized for stability and strength.

- Bulb angles - added loading capacity, typically in industrial applications.

Sizes & Thickness

Each type is available in a variety of sizes, thicknesses and finishes (black, galvanized or painted) to suit the application.

Manufacturing Process

MS Angles are typically manufactured using the hot rolling process, where steel billets are heated and passed through rollers to shape them into angles. This process ensures:

- Uniform thickness

- Consistent mechanical properties

- Good surface finish

Sizes & Thickness

They are available in various sizes and thicknesses, depending on the structural requirements. Common thicknesses range from 3 mm to 10 mm or more, and they are generally supplied in standard lengths (usually 6 or 12 meters), though custom sizes can be made.

Uses of MS Angles

MS Angles are used in a wide range of industries and structures due to their adaptability:

Construction

Commonly used as frames, reinforcements, and structural stability in residential, commercial, and industrial buildings.

Machinery & Equipment

MS Angles are well suited for making supporting frames or brackets for heavy machines due to their weld ability and strength.

Automobile Industry

Often used in defining the chassis, frames, and supporting structure of vehicles.

Warehousing & Storage

Used in the manufacturing of racks, shelves, and storage systems.

Other Uses MS Angles can be found in transmission towers, scaffolding, communication towers,

and agricultural equipment as well – a truly versatile raw material.

Available Sizes of MS Angles

- Commonly available sizes include:

- 25 × 25 × 3 mm

- 40 × 40 × 4 mm

- 50 × 50 × 5 mm

- 75 × 75 × 6 mm

- 100 × 100 × 8 mm

- 130 × 130 × 12 mm

- Custom sizes are available on request.

Benefits of MS Angles

High Strength to Weight Ratio – Suitable for all heavy load structures including; bridges, frames

and towers.

Malleable & Easy to Work With – MS angles can be easily cut drilled, or welded depending on

application.

Cost-Effective – An attractive price point as compared to other steel types without sacrificing

durability.

Corrosion Resistant – Can be galvanized or coated to extend the life span.

Environmentally Friendly- 100% recyclable, a sustainable choice in construction and fabrication.

Why Select MS Steel Hub for MS Angles?

At MS Steel Hub, we have earned the reputation of being a trustworthy MS angle dealer in Indore and a reputable MS angle supplier in Madhya Pradesh. Our services cater to a wide array of clients and customers, from a small local contractor to an industrial buyer, while providing premium quality products at a wholesale rate. Whatever your needs may be; bulk order, industrial supply, or simply affordable MS angle supplier, we will always ensure you receive the product on time and with great quality. Our focus is not only to provide steel, but to create partnerships built to last with our clientele.

Need long-lasting MS angles at the most affordable cost? Contact MS Steel Hub now to have bulk orders and delivery in time.