GST Registered – 23ACDFM9864H1ZX

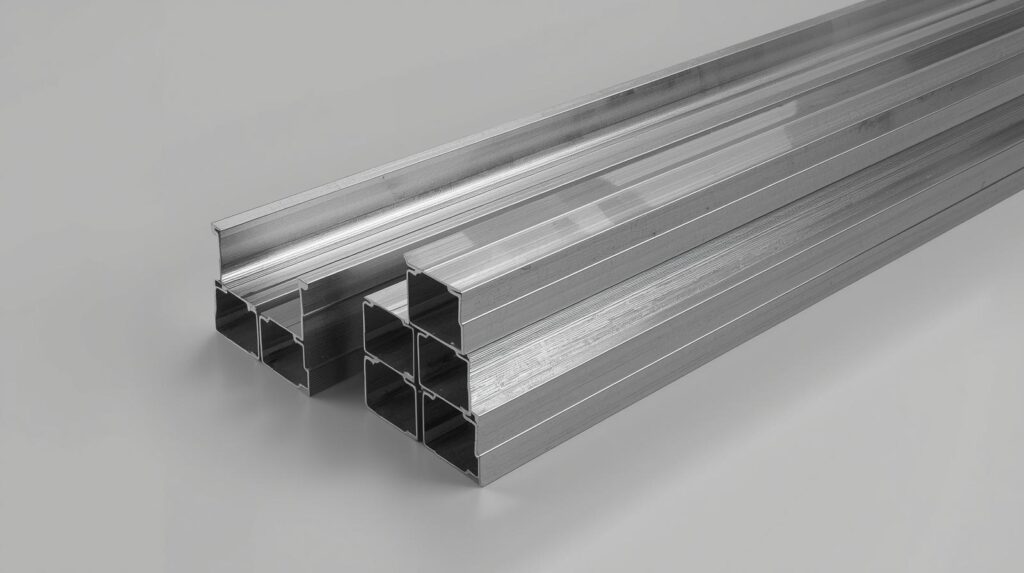

MS Channel

MS Channel – Premium MS Channels in Indore

What is an MS Channel?

MS Channel – Mild Steel Channel is a popular C-shaped Structural Steel Product that is often used in Construction and Engineering. MS Channel is extremely strong, durable, and relatively inexpensive, making it suitable for any load-bearing application including building structures, bridges, industrial sheds, and support structures. MS Channels are available in varying thicknesses and sizes, they have superb bending strength and versatility. MS channels can be used in almost any small-scale fabrication, as well as large industrial inputs.

Typical size of MS Channels

At MS Steel Hub, we stock a variety of sizes for MS channel to accommodate different job types:

- 75 x 40 mm (3 inch)

- 100 x 50 mm (4 inch)

- 125 x 65 mm (5 inch)

- 150 x 75 mm (6 inch)

- 200 x 75 mm (8 inch)

- 250 x 80 mm (10 inch)

- 300 x 90 mm (12 inch)

- (Custom sizes and bulk orders available upon request.)

Uses of MS Channels

Advantages of MS channel

High Load-Bearing Strength

MS Channels are engineered to carry substantial loads without bending or warping, which makes them a preferred option for construction and industry projects. Their strong load-bearing capacity guarantees stability during and for a long-term structural solution.

Great Workability

One of the greatest advantages when using mild steel is it's workability. MS Channels can be simply cut, welded, or drilled, allowing for fabricators and engineers to modify for a variety of uses from simple frameworks to complicated industrial designs.

Durable & Dependable

MS Channels have staying power. They resist wear and tear well against tough environments and a heavy workload. They are equally efficient when galvanized or coated, with even better resistance against corrosion, providing even more reliability.

Cost-Effective

MS Channels are relatively inexpensive when compared to other structural materials, and at an acceptable level of quality. You experience excellent strength and performance at a better price; that's why builders and industries looking for low budget options for their larger Scale projects choose them.

Recyclable

Steel is considered one of the most recycled materials in the world, and MS Channels are no exception. They are 100% recyclable, and can be reused while maintaining strength, for a better sustainable construction for the environment.

Why MS Steel Hub should be your first choice for MS Channels?

At MS Steel Hub, we are known one of the leading supplier of MS Channels and a trustworthy dealer of MS Channels Indore. We have established a solid reputation being an acclaimed industrial MS channel distributor to contractors, builders and industries throughout Madhya Pradesh.

- We have:

- Reliability and strength in all of our products

- Very affordable wholesale mild steel channel price

- Professionalism with reliable delivery

If you are a buyer looking for a mild steel channel dealer for bulk supply or someone looking to find a wholesale MS channel supplier, MS Steel Hub is your complete solution for your steel needs.

Are you in need of the best quality MS channels and have a variety of dimensions required at wholesale prices, contact MS Steel Hub- your reliable MS channel supplier located in Madhya Pradesh?”